Optical Components & Assemblies

Versatile Optical Solutions Engineered to Match Exact Requirements

FISBA manufactures a comprehensive range of optical components and assemblies, precision-engineered to shape, steer, and optimize light in demanding optical systems. From individual components to bonded assemblies, we take care of the entire chain, every optic is produced in-house, from glass processing and polishing to coating and cleanroom assembly.

Broad Portfolio for Specific Needs

Our portfolio covers plano (flat) optics, prisms, spherical lenses, rod lenses for endoscopy, integrated optical assemblies, and precision molded aspheric lenses. Each is developed with tight tolerances, advanced coatings, and expert engineering for demanding optical systems in medical, life science, industrial, and defense applications. This vertical integration allows FISBA to combine diverse technologies under one roof, offering customers compact, efficient, and traceable optical solutions that meet the highest standards of quality and reliability.

Flat Optics

FISBA’s flat (plano) optics form the foundation of advanced optical systems,are an integral part of advanced optical systems, enabling beam steering, splitting, image inversion, and reflection. Our product range includes high-precision mirrors, prisms, wedges, and beam splitters, produced with tight surface tolerances and exact angular accuracy. Complex geometries such as retroreflectors, roof prisms, and Porro prisms are manufactured to customer specifications and can be supplied as individual components or bonded assemblies.

The combination of precise manufacturing and advanced in-house coating technologies ensures outstanding performance—whether in laser applications requiring specific LIDT resistance, endoscopic imaging with broadband coatings, or metrology systems demanding sub-micron accuracy.

In medical devices, for example, prism assemblies enable changes in the viewing angle allowing more compact system designs without sacrificing performance.

Technical Data

- Angular accuracy: 3″

- Form deviation: λ/10

- Cleanliness: 5 / 3 × 0.016

- Surface polish: P4 for high LIDT resistance

By integrating optical design, polishing, coating, and testing under one roof, FISBA enables efficient prototyping, consistent serial production, and full compliance with ISO 13485 for medical-grade optics.

Aspheres

Aspherical lenses correct spherical aberrations and enable smaller, lighter, and more efficient optical systems, an essential advantage in endoscopy, laser optics, and imaging applications. FISBA offers both conventionally polished aspheres for low volume and Precision Molded Lenses for scalable, cost-efficient serial production.

Customer Benefits:

- Optimized imaging performance and resolution

- Reduced lens count and enabling low weight and small form factor

- Fully integrated manufacturing, from design to finished product. Molding, centering, and coating from one expert partner for maximum precision and reliability.

Technical Data

- Form deviation: 3 / 3 (0.5)

- Attractive selection of optical glass types (nd from 1.5 to 1.9 / νd= 21.4 to 68.1)

Precision molded lenses replicate optical surfaces directly from ultra-precise molds, maintaining nanometer-level accuracy and reducing post-processing, deal for medium- to high-volume manufacturing.

Spherical Optics

FISBA’s spherical optics deliver reliable imaging, focusing, and collimation performance across various system designs. These lenses are produced to the highest mechanical and optical tolerances, making them ideal for medical, industrial, and defense applications where precision is critical.

Technical Data

- Diameter tolerance ± 0.005 mm

- Form deviation λ/10

- Cleanliness 5 / 3 × 0.016

Each lens can be coated or integrated into assemblies with prisms or flat optics. Our ISO 13485-certified processes guarantee quality and traceability from prototype to serial production.

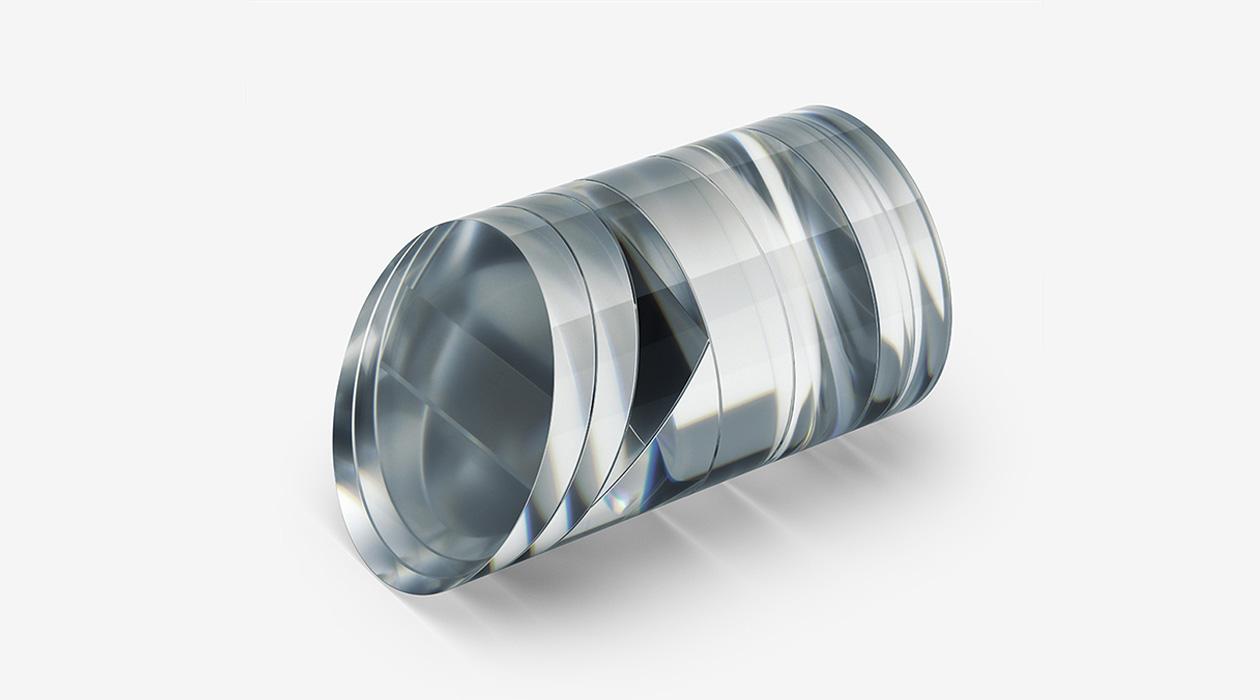

Rod Lenses

Cylindrical glass rods are essential in rigid endoscopes to bring the image from the front tip of an endoscope back to the ocular or camera coupler. These lenses are engineered to maintain uniform illumination and high contrast throughout the optical train. Configurations combining rods with corrective lenses also allow chromatic aberration compensation.

Technical Data

- Centering error 4 / < 5′

- Center thickness tolerance ± 0.02 mm

- Diameter tolerance ± 0.005 mm

Integrated Optical Assemblies – Seamless System Integration

Our optical assemblies combine flat, aspherical, spherical, and prism elements into fully aligned, ready-to-use subsystems. These assemblies are produced in cleanroom environments with micrometer-accuracy, ensuring optimal optical performance and reliability.

Typical assemblies include:

- Endoscope imaging objectives for several purposes

- Laser beam combiners and splitters

- Precision subsystems for defense optics

Why Partner with FISBA?

FISBA supports you from concept to serial manufacturing with customized optics that deliver performance, reliability, and integration efficiency .

- Complete in-house value chain—from raw glass to aligned assemblies

- Micro-optic precision: components down to 0.5 mm

- Advanced coatings and cleanroom assembly

- ISO 13485-certified manufacturing and quality control

- Proven expertise across medical, life science, defense, and laser markets