Paragraphs

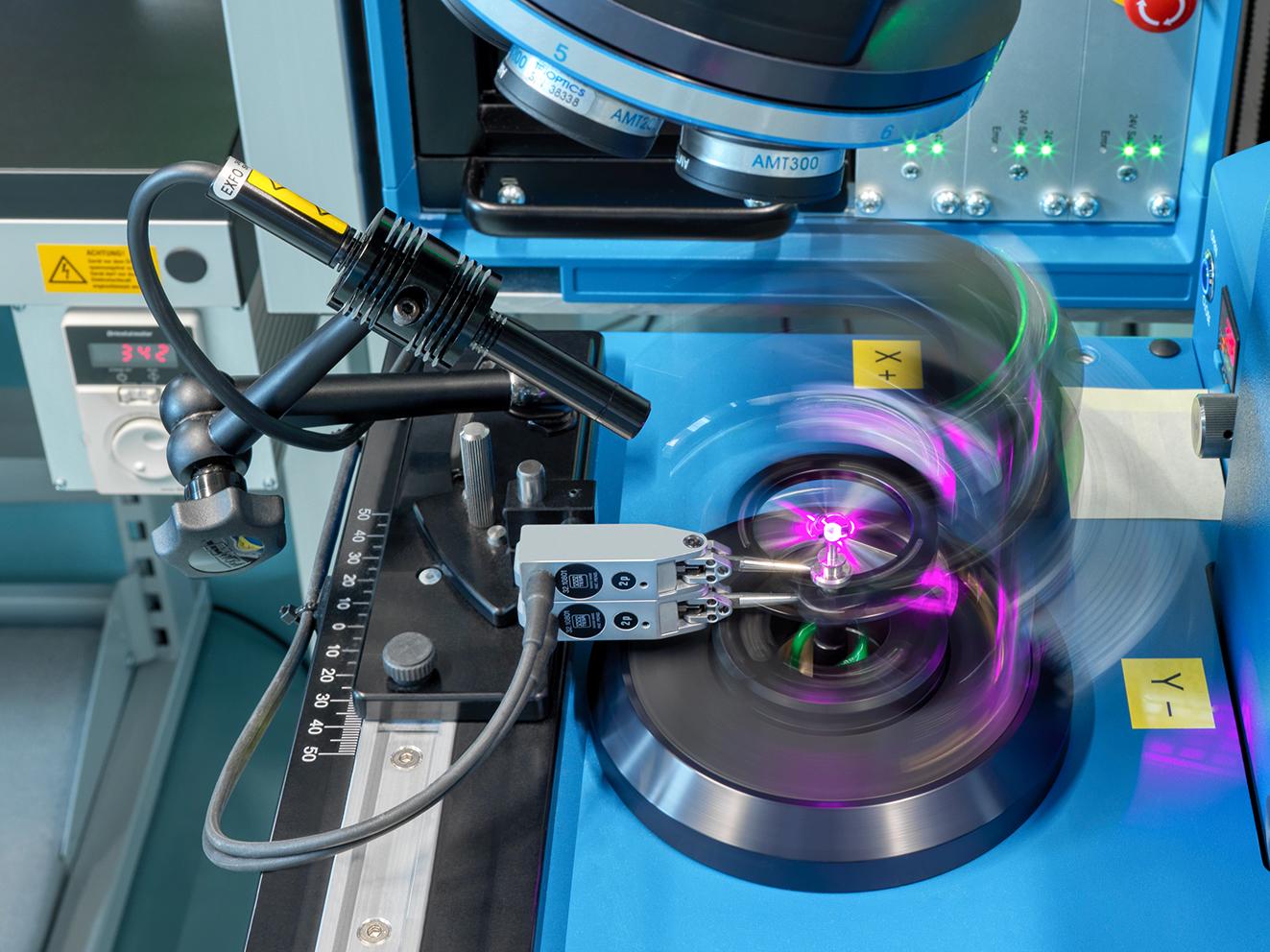

Development of Photonics Solutions

We fulfill customer wishes.

Jürg Zürcher

With us, you get photonic solutions from experienced individuals. From the tender phase to design and prototyping through to production. We look forward to impressing you with precision and high-quality products.